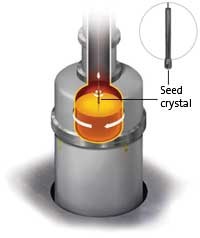

Silicon Growing Furnace

Crystal Growing

Solar World heats and melts polysilicon rock until it forms a white-hot liquid, then re-fuses the molten silicon into a single giant crystal in which all atoms are perfectly aligned in a desired structure and orientation.

Charging

The magic starts with about 250 pounds of polysilicon rocks carefully stacked in a quartz crucible. The only other ingredient is a silicon disk impregnated with a tiny amount of boron. The addition of the oron dopant ensures that the resulting crystal will bear a positive potential electrical orientation. The crucible is encased within thick walls of insulating graphite and locked inside a cylindrical furnace.

Melting

As the crystal-growing furnace heats up to temperatures ranging around 2,500 degrees Fahrenheit, its silicon contents melt into a shimmering slurry. Once computerized monitors register the right temperature and atmospheric conditions, the alchemy begins. A silicon seed crystal hung from a narrow cable attached to a rotary device atop the furnace is slowly lowered into the melt.

Growing

The crucible starts to turn, and the seed crystal begins to rotate in the opposite direction. The silicon melts and freezes onto the seed crystal, matching the seed’s crystalline structure. The crystal grows, the cable and seed slowly ascend, and the crystal elongates at a controlled width. As the growth depletes the silicon slurry, the crucible also rises.

Cooling

Flash forward about 2.5 days since the crucible was charged with polysilicon: After hours of cooling to about 300 degrees Fahrenheit, the furnace hood and shaft lift away from the crucible encasement, slowly swing to one side, and reveal a completed cylindrical crystal, ready to move to the second step and next production room.